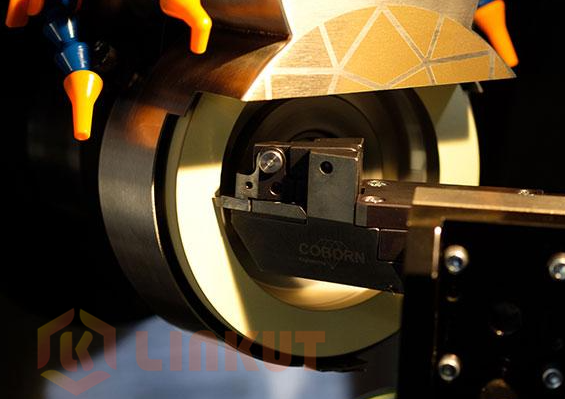

Best Choice for Grinding PCD tools With Ceramic Bonded Diamond Grinding Wheels

By comparing the process of grinding PCD tools with resin bonded diamond grinding wheels, metal bonded diamond grinding wheels, and ceramic bonded diamond grinding wheels, it is believed that ceramic bonded diamond grinding wheels are the most suitable for grinding PCD tools.

1)When resin bonded diamond grinding wheels are used to grind PCD materials, the surface accuracy of the processed PCD decreases, and in most cases, it will be curved instead of flat. However, premature detachment of diamond abrasive particles will greatly reduce the grinding efficiency of PCD materials. Resin bonded diamond grinding wheels are not suitable for processing PCD tools.

2)When grinding PCD tools with metal bonded diamond grinding wheels, due to the strong strength of the metal bonding agent, its self sharpening degree is low, and it is difficult for the abrasive particles to fall off after wear, resulting in a decrease in grinding efficiency. Moreover, if the grinding wheel is not repaired in time, it will also cause thermal damage and sharpening ability of the PCD tool surface, affecting grinding efficiency and quality.

3) When grinding PCD tools with ceramic bonded diamond grinding wheels, the characteristics of ceramic bonded grinding wheels are high hardness, good self sharpening ability, stable mechanical properties, water resistance, heat resistance, acid resistance, and low cost. The grinding process is similar to that of a metal bonded grinding wheel, but the difference is that after the diamond abrasive grains become dull, due to the moderate bonding strength and good self sharpening of the ceramic binder, the grinding wheel abrasive grains will automatically fall off when the grinding force reaches a certain value, and new abrasive grains will form, thereby preventing thermal damage to the PCD tool caused by excessive grinding force and high grinding temperature.

However, ceramic bonded grinding wheels usually need to be fired after powder pressure forming, and the uniformity of the formed body is difficult to ensure, and it is relatively brittle. Therefore, during grinding, the abrasive particles and bonding agent sometimes fall off collectively, which may cause scratches on PCD tools.

Overall, the surface quality of ceramic bonded diamond grinding wheels is good, basically similar to that of metal bonded grinding, and their grinding efficiency is extremely high, reaching four times the efficiency of metal bonded grinding.

Previous Article:none

Next Article: What Is PCD and Its Application